Ealing Broadway Station

Project outline:

INVVU were appointed to undertake the GRIP 3 – 8 Survey, Optioneering Design, Developed Design, Detailed Design, Approvals and Construction Support for new platform canopies to platforms 2/3 and 4 of Ealing Broadway Station which had recently been recategorized as a Category A station.

Location:

Ealing, Greater London W5 2NU

Client:

- GRIP Stages 3 & 4 – MTR Elizabeth Line

- GRIP Stages 5 – 8 – Novated Designer to Walker Construction (UK) Ltd

INVVU provided:

- Design Management

- Project Management

- Suite of Site Surveys including topographical, Ground Investigation, Signal Sighting and Gauge Surveys.

- Quantity Surveyor

- Structural Engineering

- Civil Engineering

- Geotechnical Engineer

- MEP Services Engineering

- Telecoms Engineering

- Earthing and bonding design

- Blast analyst

- NWR Asset Protection approval

Key Collaborators:

- Stuart Callaghan Surveyors – Topographical and platform gauge Survey

- Ashdown Site Investigation – Ground Investigations

- Counrty Clean Group – CCTV Drainage Survey

- Crayside Consultants – Earthing and Bonding Survey and Design

- Gioconda – Signal Sighting Survey and Assessment

- Optyma – Telecoms Survey and Design

- Sitech – Ground Penetrating Radar Services Survey

- WSP – Blast Analysis

- Network rail Asset Protection – DPE, DPE’s and Approvals

The Project:

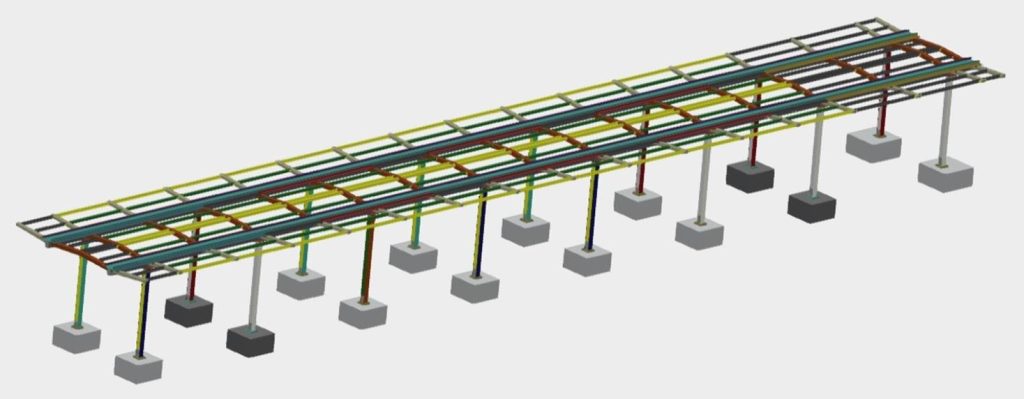

The proposal is to construct new platform canopies to the Country End of platforms 2, 3 and 4 of Ealing Broadway Station. The canopy to platform 2/3 is approximately 45m long and 8.25m wide, platform 4 canopy is approximately 8m long by 8m wide. The proposed canopy’s interface with existing platform structures such as the existing canopy of platform 4 and the waiting room and AFA stairs on platform 2/3 but are structurally independent.

Both canopies can easily be extended in bays if required in the future.

The design intent is to have modern structures that align with the modern AFA overbridge

Blast analysis – the station had recently be recategorised as a CAT A station meaning the canopies had to be designed and fabricated in such a way that they could withstand a blast from any suspected packages placed at the bases of the columns and not collapse but dissipate the anticipated blast.

Need help with your project?

Contact us to see how taking a joined up approach could benefit you.